Manufacturing Software Solutions

Custom software solutions for manufacturing operations. Optimizing production lines and quality control with enterprise-grade digital transformation.

Manufacturing Business Drivers

Manual quality control and disconnected systems create bottlenecks and quality issues in manufacturing operations.

Paper-Based Quality Control

Quality checks done on paper forms that slow production and create inconsistent results across manufacturing lines.

Production Line Delays

Equipment downtime and changeover delays reduce overall equipment effectiveness (OEE) and productivity.

Inventory Blind Spots

Limited visibility into raw materials and work-in-progress inventory leads to stockouts and production delays.

Equipment Breakdowns

Reactive maintenance approach results in unexpected failures and costly emergency repairs that halt production.

Data Silos

Production data trapped in separate systems prevents real-time decision making and optimization.

Compliance Tracking

Manual compliance documentation creates audit risks and regulatory penalties in highly regulated industries.

Solutions for Manufacturing and Logistics

Enhanced workflows integrating people, products, and data through enterprise digital solutions. We streamline shop floor operations, ensure efficient quality management, and fortify supply chains against disruptions.

Production Process Optimization

Enhanced workflows that integrate people, products, and data to streamline shop floor operations. Real-time insights enable predictive maintenance, reduce unplanned downtime, and optimize production efficiency across all manufacturing lines.

- Digitized workflows connecting production teams and departments

- Real-time machine performance and production efficiency insights

- Predictive maintenance reducing unplanned downtime

Quality Control & Compliance Management

Industrial-strength quality control systems ensuring product consistency and regulatory compliance. Automated quality checks with real-time monitoring of production metrics, defect rates, and compliance adherence reduce waste and maintain industry standards.

- Streamlined quality control processes with user-friendly data collection

- Real-time monitoring of production metrics and defect rates

- Automated quality checks integrated with production systems

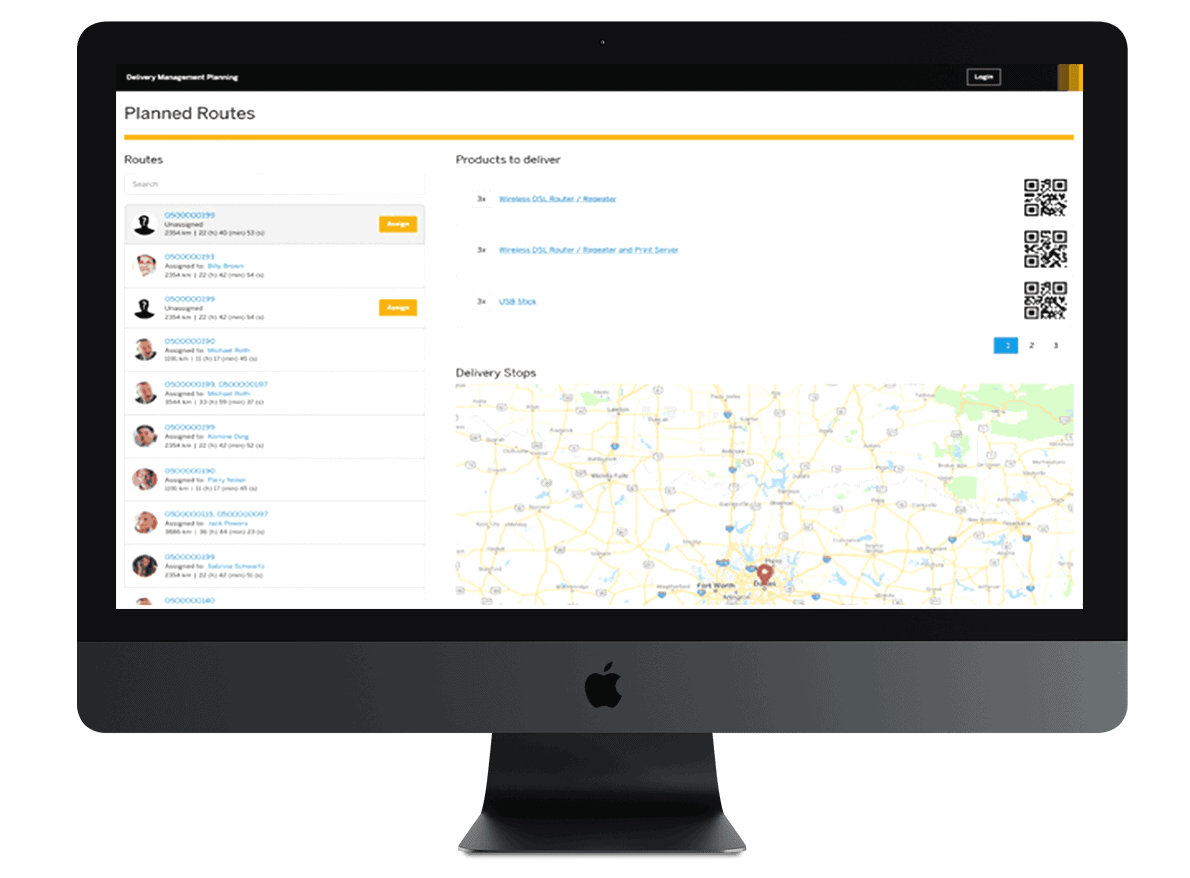

Supply Chain & Inventory Management

Dynamic supply chain management applications that track inventory levels, monitor supplier performance, and optimize procurement processes. Ensures smooth, uninterrupted material flow while fortifying supply chains against potential disruptions.

- Dynamic inventory tracking with automated reorder optimization

- Supplier performance monitoring and procurement analytics

- Supply chain disruption prevention and contingency planning

Complete Development Solutions

Full-stack enterprise development services to build, integrate, and deploy your manufacturing digital solutions.

Custom Applications

Enterprise applications tailored to your manufacturing processes

Low-Code Development

Rapid development and deployment with visual tools

Framework Apps

Pre-built manufacturing frameworks ready to deploy

AI Solutions

Smart manufacturing with predictive analytics and automation

System Integration Services

Connect your existing manufacturing systems with modern APIs and workflows

Your Path to Manufacturing Digital Transformation

A tested methodology that transforms your manufacturing operations with minimal disruption to production.

1. Production Assessment

We analyze your current manufacturing processes, production workflows, and pain points to identify optimization opportunities and bottlenecks. Then we create a clear roadmap that aligns with your production goals.

Key Outcomes

2. Solution Design

We design the system architecture and user experience specifically for your manufacturing environment and production needs. This includes detailed technical specifications and a step-by-step implementation plan.

Key Outcomes

3. Development & Testing

We build your solution using established development methods with continuous testing. Every component is tested thoroughly in staging environments to ensure reliability and performance.

Key Outcomes

4. Deployment & Training

We deploy your solution with zero impact to production operations. Our training programs ensure your manufacturing team knows exactly how to use the new system directly.

Key Outcomes

Ready to Get Started?

Schedule a consultation to discuss your specific requirements and timeline.

Schedule Consultation

Built for Your Existing Manufacturing Systems

Enterprise-grade integration with your current manufacturing infrastructure. Direct MES and ERP connectivity.

Core Capabilities

Rapid Deployment

Proven implementation methodology

Zero Production Impact

Deploys without stopping production lines

Industrial-Grade Security

Built for manufacturing environments

Industry Tested

Deployed across manufacturing facilities

Shop Floor Ready

Ruggedized tablets and mobile devices

Real-Time Production Data

Live synchronization with production systems

Technology Solutions

Common Questions About Our Manufacturing Solutions

Get answers to frequently asked questions about our manufacturing solutions.

We design our software to bridge the gap between enterprise IT systems (like ERP, MES, QMS) and operational technology (PLC, SCADA, sensors). Whether you're a manufacturer or an industrial service vendor, we ensure seamless integration across your shop floor and enterprise stack, unlocking real-time data visibility, streamlined workflows, and system interoperability without disrupting production.

We align with key transformation goals: automation of manual processes, predictive asset management, workforce enablement, and data-driven decision-making. Our solutions reduce unplanned downtime, improve quality control, and increase throughput, while supporting strategic shifts such as Industry 4.0, smart factory initiatives, and sustainability targets.

We specialize in legacy system extension, not replacement. By introducing middleware, APIs, and UI modernization layers, we digitize and connect your existing machines, HMI stations, and databases, extending the value of your current investments and making them AI- and cloud-ready.

We build the digital foundation needed for AI: structured data capture, integration across production lines, and centralized data lakes or warehouses. Whether you’re optimizing OEE, forecasting demand, or detecting quality issues, our solutions ensure your operations are ready for machine learning, computer vision, and prescriptive analytics.

Yes. Our platforms and solutions are built with modular, multi-plant architectures. We support both global manufacturers standardizing processes across sites and regional players scaling from one facility to several. Our solutions can be rolled out in phases while maintaining centralized governance and KPIs.

We equip frontline operators, technicians, and supervisors with mobile-ready tools to digitize inspections, report downtime, and collaborate in real time. This improves response times, reduces paperwork, and ensures standard operating procedures are followed consistently on the shop floor.

Yes. We capture equipment health data from sensors, PLCs, and manual inputs, applying rules-based logic and AI models for predictive maintenance. This helps maintenance teams act before failures occur, reducing production loss and spare parts costs.

We digitize quality checks, non-conformance tracking, and batch traceability from raw materials to finished goods. Our systems integrate with your QMS or ERP to ensure every defect, deviation, or spec limit violation is logged, escalated, and resolved, improving first-pass yield and audit readiness.

Our implementation process is designed around plant schedules and operational constraints. We work in close coordination with production, maintenance, and IT teams, using phased rollouts, parallel systems, and sandbox environments to ensure minimal impact on live operations.

Ready to Transform Your Manufacturing Operations?

Let's discuss your current production systems and explore how our solutions can modernize your operations.